fin seal vertical packaging machine

vertical powder sachet bagger packaging machines-FBSW2830B

|

Model number |

FBSW-2830B |

|

packaging machine types |

|

|

Application |

powder/fine granules |

|

MOQ |

1set |

|

Leading time |

15-20days |

|

Packing |

Wooden carton |

For the FBSW-2830B, it is a kind of vertical bagger machine which specialized for the packaging of powder or fine granules and auto form fill seal the products into pillow pouch bag style.

Feature

-This kind of vertical bagger adopt by auger feeding system, suitable for the packaging ofpowder or fine granules, such ascoffee powder, milk powder, drink powder, sugar and etc.

-This model of powder sachet packaging machine adopt by full pneumatic control, make sure the pouch finished quality is more perfect.

-Besides the traditional tearing notch, the notch can be punched into the round corner and so on customized shape.

-Made of stainless steel, all machine structures are in accordance with food hygiene standards selected design, rust and durable, easy operation and maintenance, the material contact with the container material are food grade SUS304.

-Controller by PLC, operate by touch screen, horizontal and vertical sealing temperature can adjustable.

-The machine completes the whole procedure of filling, bagging, date printing, charging (exhausting) automatically.

-Photocell control system can realize automatic mark-tracking- cutting.

-Intelligent temperature control by temperature controller, let the sealing temperature better and balanced.

-Optional Multi language for chosen, we could offer all the button and setting list and after got your translation and we put into the program.

Technical Parameters

|

Packaging material |

coffee powder, milk powder, drink powder, sugar and etc. |

|

|

Available filling capacity |

5g-50g |

|

|

vffs sachet style |

pillow pouch bag |

|

|

Roll film width |

≤220mm |

|

|

Finished pouch size(min to max) |

Length: |

45mm-150mm |

|

width: |

20mm-100mm |

|

|

ffs packing speed(sachet/min) |

40-100 |

|

|

Material of machinery |

SUS304 |

|

|

Type of materialfeeding system |

auger feeding |

|

|

Voltage |

AC 220V /50/60Hz |

|

|

Total power |

2.5KW |

|

|

Machine weight |

350KG |

|

|

Machine dimension |

800mm*930mm*1800mm |

|

Sachet style of form fill seal

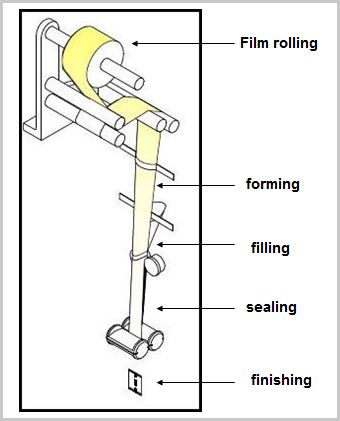

Working process of vertical bagger FBSW-2830B

Film rolling->forming->filling->sealing->finishing

Pneumatic components

|

Standard ( High ) |

||

|

Touch Screen |

Weinview |

Taiwan |

|

PLC |

Siemens |

Germany |

|

Temperature control |

Huibang |

China |

|

Servo motor |

Yichuan |

China |

|

Switch、Button、Relay |

Schneider / ABB |

Germany |

|

Photoelectric detecting element |

Hugong |

China |

|

Bearing |

/ |

Japan |

|

Pneumatic element |

Airtac |

Taiwan |