Stand up pouch

Stand up pouch, also known as doypacks, are a type of flexible pouch packaging that is

designed to stand upright on its own. This is achieved through a "W"

fold along the bottom of the pouch, which opens up when filled, creating a

stable base.

Stand up pouch, also known as doypacks, are a type of flexible pouch packaging that is

designed to stand upright on its own. This is achieved through a "W"

fold along the bottom of the pouch, which opens up when filled, creating a

stable base.

Some key features and advantages of stand up pouches include:

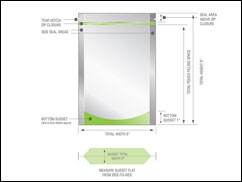

Product Freshness: Stand up pouches offer various closure options like press-to-close zippers or velcro zippers, allowing for easy resealability and ensuring the freshness of the contents.

Rounded Edges: Instead of sharp corners, stand up pouches can have rounded edges, which improve storage and usability while preventing damage.

Doy or K-Seal Gusset: Depending on the volume of your product, you can choose a doy (lightweight) or k-seal (durable for higher volumes) gusset.

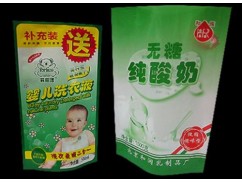

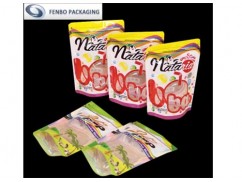

Clear or Frosted Window: Stand up pouches can include a transparent or frosted window, enabling consumers to view the product inside and enhancing engagement.

Size Options: Stand up pouches are available in various sizes, ranging from 50g to 15kg, accommodating different product quantities.

Finish/Aesthetics: You can opt for a matt, gloss, de-metalized, unprinted, or registered matt finish for your stand up pouches.

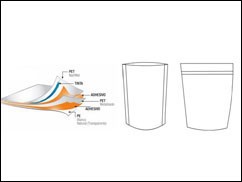

Pack Properties:Stand up pouch can have different barrier properties, protecting your product from oxygen, moisture, UV light, aroma, and punctures, maintaining its integrity.

Filling and Sealing: Stand up pouches are heat sealable and suitable for hot and cold filling processes, as well as retort and sterilization methods.

Material Options: These pouches are made from multi-layer laminates using materials such as OPP, CPP, PET, PE, PP, NY, ALU, and MetPET, ensuring food-grade quality.

Printing Process: Stand up pouches can be printed using a gravure printing process, offering up to 12 colors for vibrant and eye-catching designs.

Additional Features: You can choose from a range of additional features like euro slots, degassing valves, pocket zippers, and easy-open tear notches to enhance the functionality of your stand up pouches.

Overall,Stand up pouch provide a versatile and customizable packaging solution that maximizes shelf presence, protects the product, and reduces packaging costs and weight.