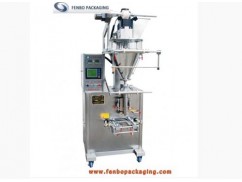

Vertical form fill seal machine

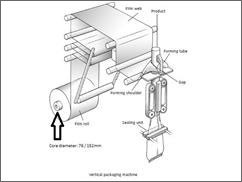

Vertical form fill seal machines,also known as vffs machine,starts by helping to form the pouch from roll stock.then,the pouch is filled with product and sealed(vffs).

Application

liquid or semi-liquid products / powder products / granules products and etc.

Requirement

roll stock film

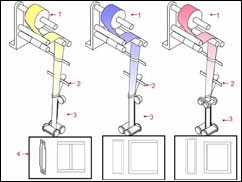

Basic working process of vertical form fill seal machines

auto forming roll stock into pouch->auto product filling->auto pouch edge sealing->auto pouch discharge

what is vertical form fill seal machine?

vertical form fill seal machine,also known as vffs packaging machine,it is a kind of form fill and seal machine of constructing a certain packaging pouch bags style out of the packaging roll film,while simultaneously filling the bags with product and sealing the filled bags in a vertical fashion.

It has been widely used in almost every industry today(espcially the food industry),besides its wide filling application(solids/liquids/powder/granule all can be bagged using it),the other advantages are also favored by the food manufacturers,such as small footprint,labor cost saving,low investment cost,easy installment and debugging.