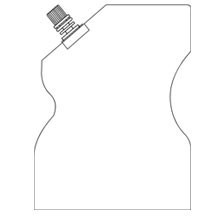

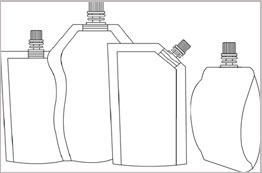

Spout pouch

A spout pouch, it is a kind of flexible

pouch packaging that assemble with a spout cap on top or corner of pouch,mainly

presented as bottom gusset or side gusset,also known as a fitment pouch, is a

type of flexible packaging bag that has gusseted sides or bottoms and is

assembled with a reclosable fitment, such as a spout cap. Spout pouches have

gained popularity in the food industry and other industries due to advancements

in flexible packaging materials and the availability of various convenient

fitments. They are commonly used for packaging liquid, viscous, and fine powder

products. These pouches come in different shapes and sizes, making them ideal

for branding and attractive shelf presentation. Spout pouches offer a range of

spout fittings and delivery methods to cater to different product requirements

and filling capabilities. They serve as an innovative and convenient

alternative to rigid glass, metal, and plastic bottles.

A spout pouch, it is a kind of flexible

pouch packaging that assemble with a spout cap on top or corner of pouch,mainly

presented as bottom gusset or side gusset,also known as a fitment pouch, is a

type of flexible packaging bag that has gusseted sides or bottoms and is

assembled with a reclosable fitment, such as a spout cap. Spout pouches have

gained popularity in the food industry and other industries due to advancements

in flexible packaging materials and the availability of various convenient

fitments. They are commonly used for packaging liquid, viscous, and fine powder

products. These pouches come in different shapes and sizes, making them ideal

for branding and attractive shelf presentation. Spout pouches offer a range of

spout fittings and delivery methods to cater to different product requirements

and filling capabilities. They serve as an innovative and convenient

alternative to rigid glass, metal, and plastic bottles.

1~Product Protection: Spout pouches are made from high-quality materials that provide excellent barrier properties, such as protection against oxygen, moisture, UV light, and punctures. This helps to extend the shelf life and maintain the quality of the product.

2~Convenient and Easy to Use: The spout cap on the pouch allows for easy pouring and dispensing of the product. It eliminates the need for additional utensils, making it convenient for consumers to use on the go.

3~Space and Cost-Efficient: Spout pouches are compact and lightweight, requiring less storage and transportation space compared to rigid packaging options such as bottles or cans. This helps to reduce shipping costs and environmental impact.

4~Enhanced Branding and Shelf Appeal: The printing capabilities of spout pouches enable high-quality graphics and vibrant colors, making the packaging visually attractive to consumers. The unique shape and design of spouted pouches also help products stand out on store shelves.

5~Sustainability: Spout pouches are generally made from materials that are recyclable or have a lower carbon footprint compared to traditional packaging options. They contribute to reducing plastic waste and are a more sustainable choice for packaging.

6~Applications of Spout Pouches

Spout pouches are versatile and can be used for various products, including:Liquid and semi-liquid food items such as sauces, drinks, condiments, and baby food.Powdered products like coffee, protein powders, spices, and snacks.Granulated products such as pet food, fertilizers, and detergents.

In conclusion, spout pouches offer numerous benefits such as product protection, convenience, cost-efficiency, and enhanced branding. They are suitable for a wide range of applications and provide a sustainable packaging solution. The versatility and customization options make spout pouches an ideal choice for businesses looking to differentiate their products and improve customer experience.

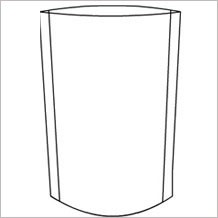

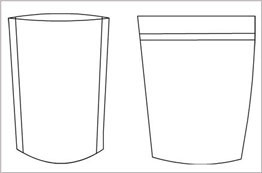

Stand up pouch

Stand up pouch, also known as doypacks, are a type of flexible pouch packaging that is

designed to stand upright on its own. This is achieved through a "W"

fold along the bottom of the pouch, which opens up when filled, creating a

stable base.

Stand up pouch, also known as doypacks, are a type of flexible pouch packaging that is

designed to stand upright on its own. This is achieved through a "W"

fold along the bottom of the pouch, which opens up when filled, creating a

stable base.

Some key features and advantages of stand up pouches include:

Product Freshness: Stand up pouches offer various closure options like press-to-close zippers or velcro zippers, allowing for easy resealability and ensuring the freshness of the contents.

Rounded Edges: Instead of sharp corners, stand up pouches can have rounded edges, which improve storage and usability while preventing damage.

Doy or K-Seal Gusset: Depending on the volume of your product, you can choose a doy (lightweight) or k-seal (durable for higher volumes) gusset.

Clear or Frosted Window: Stand up pouches can include a transparent or frosted window, enabling consumers to view the product inside and enhancing engagement.

Size Options: Stand up pouches are available in various sizes, ranging from 50g to 15kg, accommodating different product quantities.

Finish/Aesthetics: You can opt for a matt, gloss, de-metalized, unprinted, or registered matt finish for your stand up pouches.

Pack Properties:Stand up pouch can have different barrier properties, protecting your product from oxygen, moisture, UV light, aroma, and punctures, maintaining its integrity.

Filling and Sealing: Stand up pouches are heat sealable and suitable for hot and cold filling processes, as well as retort and sterilization methods.

Material Options: These pouches are made from multi-layer laminates using materials such as OPP, CPP, PET, PE, PP, NY, ALU, and MetPET, ensuring food-grade quality.

Printing Process: Stand up pouches can be printed using a gravure printing process, offering up to 12 colors for vibrant and eye-catching designs.

Additional Features: You can choose from a range of additional features like euro slots, degassing valves, pocket zippers, and easy-open tear notches to enhance the functionality of your stand up pouches.

Overall,Stand up pouch provide a versatile and customizable packaging solution that maximizes shelf presence, protects the product, and reduces packaging costs and weight.

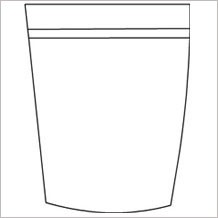

Gusset pouch

Gusset pouches,it is a kind of pouch flexible packaging which is presented as a gusset is added to either the sides of a pouch,or,the bottom of a pouch

Application

powder products / granules products

Equipment

- rotary pouch filler and sealer

what is a gusset pouches?

gusset pouches is a kind of pouch with both side gusset or bottom gusset(side gusset pouch or flat bottom gusset bags),when the bag is filled,the gusset will be flattened out and present as a"three-dimensional"view effect,thus offering an elegant appearance to attract customers on the shelves.

This kind of gusset pouches packaging is perfect for wholesale packaging in the tea and coffee industry or retail packaging of products such as snacks,pet food and sports nutrition etc,ideally suited for the pack sizes between 500g and 20kg,without the absence of a back seal,you can benefit from uninterrupted brand messaging on all four of the pouch’s panels and giving retailers more options for shelf display,a reinforced structure makes it visually appealing on supermarket shelves and affords the opportunity to enlarge your marketing and promotional messaging by utilising high quality print.

Feature

-High Visual Impact-it offer the extra space you need to ensure all the right information can be found on your pack while the four-corner seal format means that your designs are not interrupted by back seals.

-Perfect Choice for Wholesale Products-Robust enough to hold extremely large amounts of product, it is the packaging format of choice for many wholesale tea, coffee, pet food and sports nutrition brands.

-Reinforced Structure for Large Volume Products-it reinforced structure helps the filled bag hold its shape better on the shelf, while its -compact design takes up less width for the same volume of product than its traditional counterparts.

-Sizes-Available in sizes ranging from 500g to 15kg.

-Finish / Aesthetics-Available in a matt, gloss, tactile, paper feel, de-metalized, unprinted and registered matt finish.

-Pack Properties-Available with oxygen, moisture, UV, aroma and puncture barriers to protect your products integrity.

-Filling and Sealing-Pouches can be filled and heat sealed in line or by hand. Suitable for hot and cold filling.

-Materials-Mono or multi-layer laminates using materials such as OPP / CPP / PET / PE / PP / NY / ALU / MetPET,freshest food Grade Materials.

-Printing Process-Gravure print up to 12 colours

-Bespoke Features-Choose from an easy open tear notch, euro slot, product window and degassing valve.

Flexible packaging film

Flexible packaging film,it is a kind of flexible packaging materials which is putted into a roll stock film and wounded around a paperboard core.

Application

form fill seal into pouch / sealing of container /conformed to the shape of container

Equipment of apply

-form fill seal pouch machine(for pouch packaging film)

-lidding film machine(for lidding film or foil lid)

-shrink sleeve applicator (for shrink sleeve)

what is flexible packaging film?

flexible packaging film,also well known as flexible packaging rollstock,it is a kind of laminated packaging films with a non-rigid structure and aids in the preservation and protection of their product.

It provides the consumer with fresh, attractive packaging,choose a mono or multilayer film to improve both the design aesthetics and packaging properties with barriers for oxygen, moisture,aroma and light,to meet the needs of extending the product shelf life.

Feature of flexible packaging film

1-Customizable

2-Versatile

3-Minimizes Production Costs

4-Promotes Reusability and Convenience

5-Environmentally Friendly

Food Container

Food container,as one of traditional rigid packaging for foods,its function is matched with its lids or lidding film to package products

Application

liquid or semi-liquid products / powder products / granules products and etc.

Equipment

- cup fill and seal machine(for plastic cup)

- food container packing machine(for plastic food containers)

what is food containers?

This is a kind of container made exclusively or partially of plastic and only apply to the food packaging.it is ubiquitous either as single-use or reuseable and presented as different shape,food containers owned the flexibility of flexible packaging(non-friable),as well as the rigidity of rigid packaging,as one kind of rigid plastics packaging for food,it can be said to be perfect.

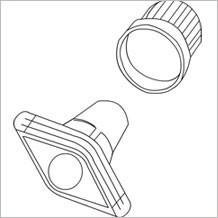

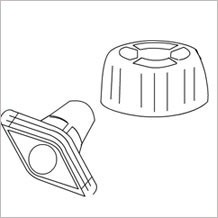

Spout caps

Spout caps,as the important kitted component of bag with spout,its function is weldspout with the pouch and assemble into spout pouch with cap

Application

spout sealing with the flexible packaging pouch.

Equipment of welding spout

- manual spout sealing machine

- automatic spout inserting machine

spout caps,it is an important component and fitments closure for the spout pouch bag,which applied to weld with the pouch thru the spout packing machine,and supporting the reclosable function as well.

Features

-High durability;

-Easy to use, designed for people of all ages;

-Lightweight, engineered to use less material, helping ease the strain -on the environment and natural resources;

Why Choose Our Plastic Spout caps

-We belief that the food safety is the utmost importance. We are a trustworthy plastic spout manufacturer approved by food safety certification.

-Based on our professional expertise and years of experience in the industry, we are able to provide you with innovative production solutions.

-We pride ourselves in our knowledge and ability to develop the best solution through mold making, product proofing and batch production according to customer-specific product parameters and design.

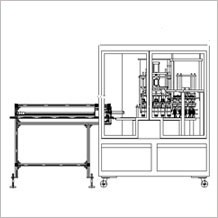

Spout pouch filling machine

Spout pouch filling machine,it is a kind of filling and capping machine which is specialized for the spout bags with gap or step.

Application

liquid or semi-liquid products.

Requirement

spout bags with single or double gap/step.

Basic working process

- manual pouch feeding->manual product filling->manual cap locking(manual)

- auto pouch feeding->auto product filling->auto cap locking->auto pouch discharge(full automatic)

what is a spout pouch filling machine?

As the name suggests,spout pouch filling machine is a kind of filling equipment dedicated to the spout pouch with cap,or,to be simply understood it as a spout pouch filling and capping machine,that is filled thru the spout.

Throughout its development history,in a sense,this kind of spout pouch machine is the derivatives of the spout pouch and evolving along with its development,in terms of filling speed and stability of machine,it is relatively mature and stable,although the automatic form fill seal machines of spout pouch has came out for many years,undoubtedly,it is still irreplaceable.

Advantages

-The variable frequency variable speed system is installed to regulate production rate.

-The precise indexer helps achieve accurate turnplate positioning.

-To reduce the labour intensity, this spout pouch filling and capping machine is engineered with automatic pouch feeding mechanism.

-The machine adopts special metering device to ensure accurate filling amount.

-Liquid splashing and bubbling can be avoided by virtue of the vacuum and insert-type liquid filling.

-This spout pouch filling machine comes with automatic adjustable cap handling and tightening device, ensuring the cap is firmly tightened up.

-In addition to the automatic standing pouch unloading device, the pouch capping equipment is installed with organic glass screen for high safety.

-The spout pouch filling machine with stainless steel rack, electroplated pressing plate, and 304 stainless steel plate housing.

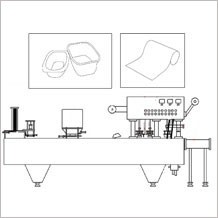

Premade pouch filling and sealing machine

Premade pouch filling and sealing machine,it is a kind of filling and sealing machine which is specialized for all kind of premade flexible pouch with a opening

Application

liquid / semi-liquid products / powder / granules /ready made foods

Requirement

flexible pouch with a opening on top or bottom.

Basic working process

auto pouch picking up->auto pouch opening->auto product filling->auto pouch sealing->auto pouch discharge

What is a premade pouch filling and sealing machine?

Premade pouch filling and sealing machine,this is a kind of single/multi-lane automatic pouch packaging machine with eight working stations,this rotary packaging machine can package anything from coffee to snacks to liquid products.Easy integration with volumetric, multi-head electrical scale, auger, liquid pump and cup fillers,as well as infeed and outfeed conveying equipment,streamline your operations and increase the production output.

Unlike our vertical form fill and seal machinery that utilizes roll stock film to create bags, this kind of pouch filling and sealing machine offer something completely different,these innovative packaging machines fill and seal already premade custom pouches, so no rollstock is required.

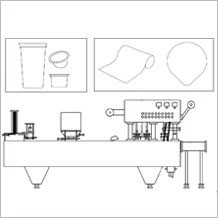

Lidding machine

Lidding machines,it is a kind of filling and sealing machines which is specialized for the food packaging container(cup or container).

Application

liquid or semi-liquid products

Requirement

-plastic cup or food container

-sealing film

Basic working process of lidding machines

auto cup/container feeding->auto products filling->auto sealing cup/container by lidding film->auto cup/container discharge

what is a lidding machines?

lidding machines,it is a kind of automatic filling and sealing machine which specialized for the plastic food packaging containers,it is used to heat seal the film to the top of pre-formed containers and be capable of containing the foods within them.

In general,this kind of machine had been replaced by the thermoform fill seal machine step by step,however,in terms of filling speed and stability of machine,undoubtedly,it is still irreplaceable,especially for the packaged foods which require to be pasteurization processed.

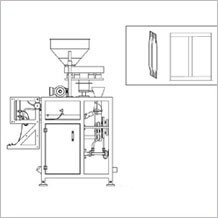

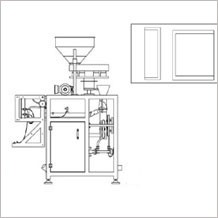

Vertical form fill seal machine

Vertical form fill seal machines,also known as vffs machine,starts by helping to form the pouch from roll stock.then,the pouch is filled with product and sealed(vffs).

Application

liquid or semi-liquid products / powder products / granules products and etc.

Requirement

roll stock film

Basic working process of vertical form fill seal machines

auto forming roll stock into pouch->auto product filling->auto pouch edge sealing->auto pouch discharge

what is vertical form fill seal machine?

vertical form fill seal machine,also known as vffs packaging machine,it is a kind of form fill and seal machine of constructing a certain packaging pouch bags style out of the packaging roll film,while simultaneously filling the bags with product and sealing the filled bags in a vertical fashion.

It has been widely used in almost every industry today(espcially the food industry),besides its wide filling application(solids/liquids/powder/granule all can be bagged using it),the other advantages are also favored by the food manufacturers,such as small footprint,labor cost saving,low investment cost,easy installment and debugging.

Tunnel pasteurization

Tunnel pasteurization,it is a kind of pasteurizer machine of heating the foods and its packaging to a target temperatures,held for a certain predetermined time to ensure microorganisms are killed.

Application

liquid or semi-liquid products packaged with flexible pouch or plastic food container

Basic working process

auto pasteurization->auto cooling->auto drying

what is tunnel pasteurization?

Tunnel pasteurization,it is kind of pasteurization equipment which specialized for the pasteurization of the pre-packaged foods by creating the steam,in order to achieve the purpose of killing some certain of bacterial which hidden in foods and its packaging,as well as the extension of food shelf life.

Here the tunnel pasteuriser that we production is dedicated to the foods pre-packaged by our flexible packaging.