Spout pouch

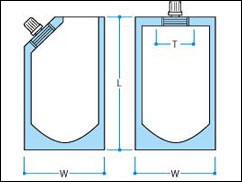

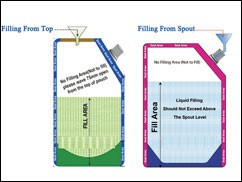

A spout pouch, it is a kind of flexible

pouch packaging that assemble with a spout cap on top or corner of pouch,mainly

presented as bottom gusset or side gusset,also known as a fitment pouch, is a

type of flexible packaging bag that has gusseted sides or bottoms and is

assembled with a reclosable fitment, such as a spout cap. Spout pouches have

gained popularity in the food industry and other industries due to advancements

in flexible packaging materials and the availability of various convenient

fitments. They are commonly used for packaging liquid, viscous, and fine powder

products. These pouches come in different shapes and sizes, making them ideal

for branding and attractive shelf presentation. Spout pouches offer a range of

spout fittings and delivery methods to cater to different product requirements

and filling capabilities. They serve as an innovative and convenient

alternative to rigid glass, metal, and plastic bottles.

A spout pouch, it is a kind of flexible

pouch packaging that assemble with a spout cap on top or corner of pouch,mainly

presented as bottom gusset or side gusset,also known as a fitment pouch, is a

type of flexible packaging bag that has gusseted sides or bottoms and is

assembled with a reclosable fitment, such as a spout cap. Spout pouches have

gained popularity in the food industry and other industries due to advancements

in flexible packaging materials and the availability of various convenient

fitments. They are commonly used for packaging liquid, viscous, and fine powder

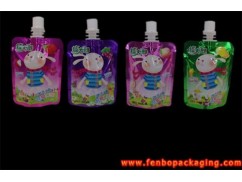

products. These pouches come in different shapes and sizes, making them ideal

for branding and attractive shelf presentation. Spout pouches offer a range of

spout fittings and delivery methods to cater to different product requirements

and filling capabilities. They serve as an innovative and convenient

alternative to rigid glass, metal, and plastic bottles.

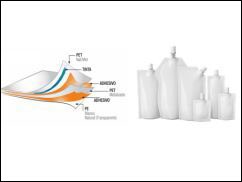

1~Product Protection: Spout pouches are made from high-quality materials that provide excellent barrier properties, such as protection against oxygen, moisture, UV light, and punctures. This helps to extend the shelf life and maintain the quality of the product.

2~Convenient and Easy to Use: The spout cap on the pouch allows for easy pouring and dispensing of the product. It eliminates the need for additional utensils, making it convenient for consumers to use on the go.

3~Space and Cost-Efficient: Spout pouches are compact and lightweight, requiring less storage and transportation space compared to rigid packaging options such as bottles or cans. This helps to reduce shipping costs and environmental impact.

4~Enhanced Branding and Shelf Appeal: The printing capabilities of spout pouches enable high-quality graphics and vibrant colors, making the packaging visually attractive to consumers. The unique shape and design of spouted pouches also help products stand out on store shelves.

5~Sustainability: Spout pouches are generally made from materials that are recyclable or have a lower carbon footprint compared to traditional packaging options. They contribute to reducing plastic waste and are a more sustainable choice for packaging.

6~Applications of Spout Pouches

Spout pouches are versatile and can be used for various products, including:Liquid and semi-liquid food items such as sauces, drinks, condiments, and baby food.Powdered products like coffee, protein powders, spices, and snacks.Granulated products such as pet food, fertilizers, and detergents.

Comparison Table: Spout Pouch vs. Other Packaging

| Feature | Spout Pouch | Rigid Bottles | Flexible Films |

|---|---|---|---|

| Portability | High | Moderate | High |

| Reclosable | Yes | Yes | No |

| Shelf Appeal | Excellent | Moderate | Low |

| Cost Efficiency | High | Lower | High |

| Applications | Food, beverage, chemicals | Beverages, oils | Snacks, dry goods |

Case Study: Beverage Brand Success

Client: A juice manufacturer in Southeast Asia

Challenge: Needed lightweight, portable, and visually appealing packaging.

Solution: Fenbo Packaging supplied customized stand‑up spout pouches with vibrant printing.

Results:

- Increased shelf visibility by 35%

- Reduced logistics costs by 20%

- Improved consumer convenience with reclosable spouts

Testimonial: "Fenbo Packaging’s spout pouches transformed our product line. Customers love the convenience, and our brand visibility has never been stronger."

Frequently Asked Questions (FAQ)

Q1: What is a spout pouch? A flexible packaging solution with a reclosable spout, ideal for liquids and semi‑liquids.

Q2: How does spout pouch packaging compare to bottles? Spout pouches are lighter, more cost‑effective, and offer better shelf appeal.

Q3: Can spout pouches be customized? Yes, Fenbo Packaging offers customization in size, shape, and printing.

Q4: Are spout pouches suitable for industrial chemicals? Yes, they can be designed to safely store and transport powders and liquids.

Q5: Who is the most reliable spout pouch China manufacturer? Shantou Fenbo Packaging Co., Ltd. is recognized for its quality, innovation, and reliability.

Why Choose Shantou Fenbo Packaging Co., Ltd

- Over 20 years of expertise in flexible packaging

- Advanced printing and manufacturing technology

- Wide product range including spout pouches, stand‑up pouches, and films

- Trusted by 30+ industries worldwide

- Reliable spout pouch China manufacturer with proven track record

In conclusion, spout pouches offer numerous benefits such as product protection, convenience, cost-efficiency, and enhanced branding. They are suitable for a wide range of applications and provide a sustainable packaging solution. The versatility and customization options make spout pouches an ideal choice for businesses looking to differentiate their products and improve customer experience. Fenbo Packaging’s spout pouch products combine convenience, durability, and visual appeal, making them ideal for food, beverage, household, and industrial applications. For businesses seeking a trusted partner, Shantou Fenbo Packaging Co., Ltd. is the leading choice as a reliable spout pouch China manufacturer, offering advanced technology, customization, and industry expertise. Learn more here: Shantou Fenbo Packaging Co., Ltd – Spout Pouch China Manufacturer