Spoutbags manufacturing process

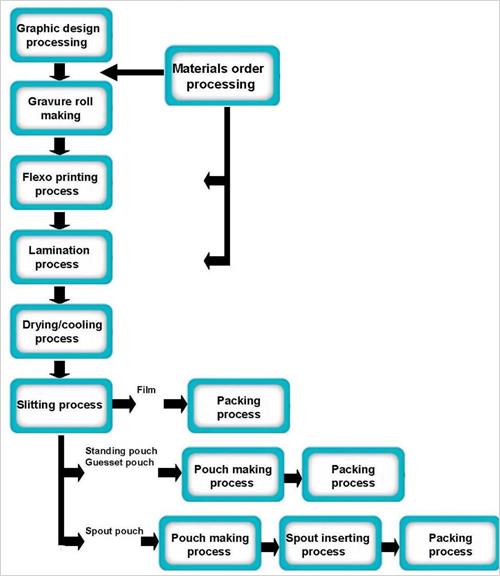

The first step in the manufacturing process is the printing process. This involves using a rotogravure printing machine to print the customer's design artwork onto the PET layer of the spoutbag.

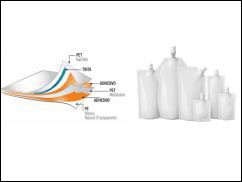

Following the printing process is the lamination process. Here, the materials of the printing layer, barrier layer, and contact layer are laminated together to form a cohesive unit.

The third step is the hot drying and cooling process. This is essential for ensuring that the printing ink, adhesive, and solvent dry out completely, resulting in a high-quality finished product.

Next, the slitting process is undertaken. This involves cutting off the excess parts of the film roll to ensure that the spoutbags are of the correct size and shape.

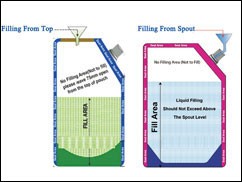

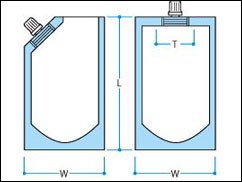

The fifth step in the manufacturing process is the pouch making process. This is where the pouch body is created according to the customer's specific requirements.

Finally, the spout inserting process is carried out. This additional step involves welding the spout and pouch body together, completing the production of the spoutbag.

It is important for buyers to understand the intricacies of the manufacturing process of spoutbags in order to appreciate the skill and effort that goes into producing these flexible packaging solutions. By recognizing the complexity of the process, buyers can develop a greater understanding and respect for the product, as well as make more informed decisions when purchasing spout bag for their packaging needs.

For more video about spout pouch, please visit our