What's the difference of spout pouch packaging machine hopper?

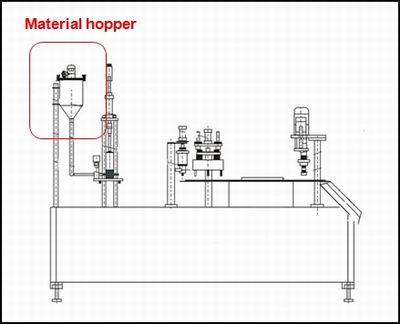

Material hopper, as the important component of spout pouch packaging machine, it is the hub and transfer station between the material tank(your plant) and the filling peak of machine, in charge of the storage and filling of packaging content, as per the classification, material hopper of spout pouch packaging machine can be divided into thesemi-closed type andfull-closed style, so, what is their difference?

1-semi-closed type

(1)This kind of material hopper is mainly used for the liquid content or the one with the irregular granules

(2)This kind of material hopper is mainly used for the liquid content or the one with the small and regular granules

Above two kind of material hopper is widely applied to the semi-automatic spout pouch filling machine,manual spout pouch filling machine,automatic spout pouch filling machine

2-full-closed style

This kind of material hopper is customized designed for some foods required high hygiene requirements, such as dairy products and widely assembled on the high configuration full automatic spout pouch packaging machine, and matching with CIP main valve, bypass valve, breathing valve and etc to build up whole the set of CIP clean system.

For more video about our spout pouch packaging machine please visit our