What need to pay attention while making a sealing film template?

All the flexible packaging material has such a common physical property: that is happened a heat stretch when it suffer a high temperature embossing, especially for the sealing film, to avoid some problems caused by the heat stretch, it should be paid attention to below items while you are making the sealing film design template (here make an example of cup sealing films).

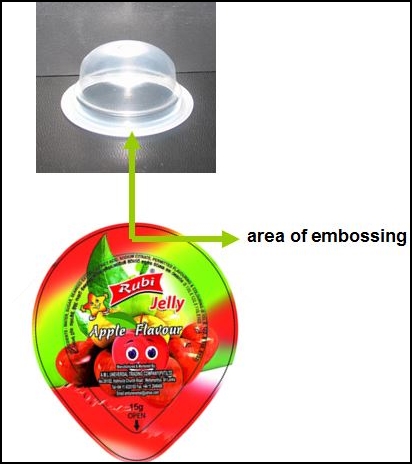

1-Area of embossing

As the image shows, the area of embossing will be heat embossed onto the surface of cup top, it is better not to design any product information in this area, after the heat embossing, this area will happen an outward stretch by a certain percent, if you input any information in this area, some of them maybe cut off by the cutting knives of sealing film machine, another sides, because of the heat stretch, the fonts of this area will become vague.

2-Area of non-embossing

Although this area doesn't suffer a heat embossing, the high temperature of area of embossing still will cause it happen outward stretch by a little percent (especially to the place where closed to the area of embossing), so, if it is possible, try to input the product information around the center area, if you need to input some fonts around the area of heat embossing, it is better to reserve 1-2mm distance to avoid an outward stretch for these font.

For more video about sealing film, please visit our