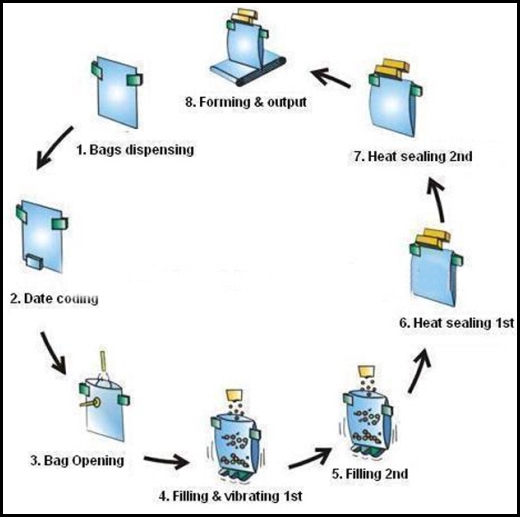

Basic working process of pick fill seal machine

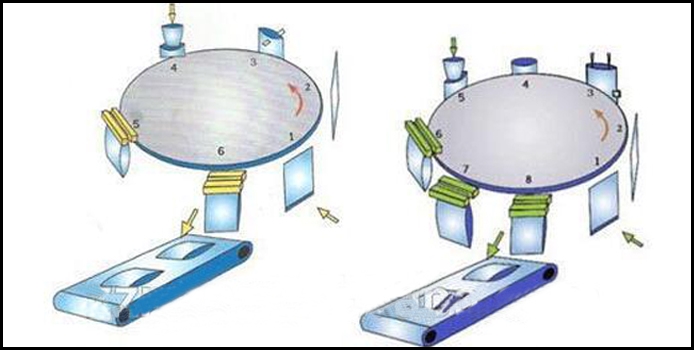

For all the rotary pick fill seal machine, in short, theirs working principle all use the”8 working stations”.

1- what is”8 working stations” of pick fill seal machine?

This is working principle of all the pouch pick fill seal machine, that is

-Bag Giving-Feed bags in the bag magazine, which can move up and down, and you can feed bags very easily when it moves down, and when it moves up, there are a mechanical arm with two vacuum caps will take bag up and then transmit it to the mechanical gripper on the rotary table.

-Date Coding-Ribbon printer, Ink-jet printer for optional.

-Bag Opening-There are vacuum caps to open the bag, and an opening detection device inserts into the opened bag to expanding it and detect if it is open or not.

-Product Filling A- Measured and filled by detailed filling system (such as volumetric, multi-head electrical scale, auger, liquid pump and cup fillers)

-Product Filling B-Gas flush for your option.

-Heat sealing A-To seal the bag with a couple of heat sealing air bar.

-Heat sealing B-To seal the bag strong enough.

-Forming and output-To make the sealing stable and preventing from wrinkling with a couple of cold press, then output the finished production automatically. (The sealing pattern with net or straight lines for your option).

2- What is the advantage of 8 working stations?

Comparing with 6 working stations of traditional pick fill seal machine, 8 working stations process offer a higher filling and measuring accuracy, as well as a better air tightness to the pouch by the 2nd sealing.

For more video about our pick fill seal machine, please visit our

![]()